Studio

Digital Fabrication

In this studio, students have access to digital fabrication technologies such as FFF and SLA 3D Printing, 3D Scanning and Laser Cutting.

Digital Fabrication Studio

These tools are versatile and can be applied at various stages of a design process. Students can use them from the initial concept phase to development, allowing them to quickly bring their ideas to life in physical forms, test their designs for functionality and aesthetics, and speed up the process of refining their creations. Due to their precision and repeatability, these tools are also suitable for final complex and detailed high-fidelity prototypes.

The studio targets mainly Industrial and Accessory Design study lines, but all students are welcome to access it, provided they align their expectations with the studio manager and meet the necessary training requirements.

Here is a brief description of the technologies available:

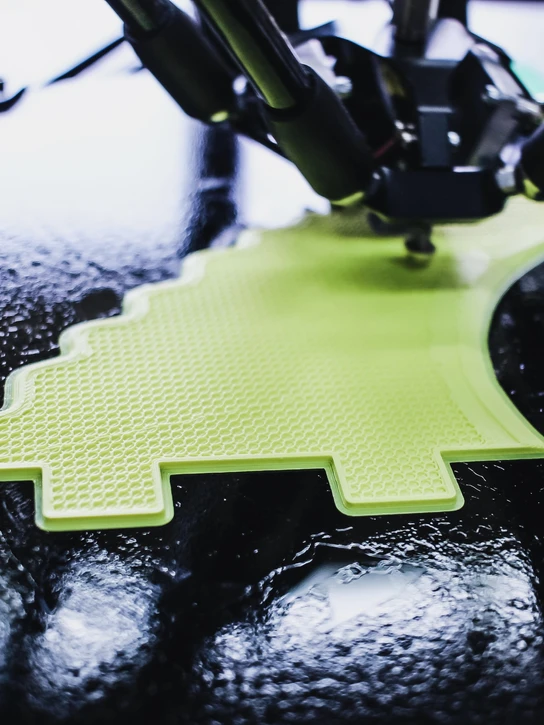

- FFF (Fused Filament Fabrication) 3D Printing: FFF 3D printers work by heating and extruding thermoplastic filament to create 3D objects layer by layer. This type of 3D printing is great for creating prototypes and functional models.

- SLA (Stereolithography) 3D Printing: SLA 3D printers use a process that involves curing liquid resin with an ultraviolet laser to build 3D objects with intricate details and smooth surfaces. This method is excellent for creating high-detail prototypes and artistic designs.

- Laser Cutting: Laser cutting machines use a high-powered laser to cut through various materials like wood, plastic, and acrylic with precision. This tool is handy for creating intricate patterns, architectural models, and signage.

- 3D Scanning: 3D scanners capture the physical geometry of an object to create a digital model. This can be useful for reverse engineering, replicating existing objects, or integrating scanned objects into new designs.