Can workwear become circular? A new project shows the way

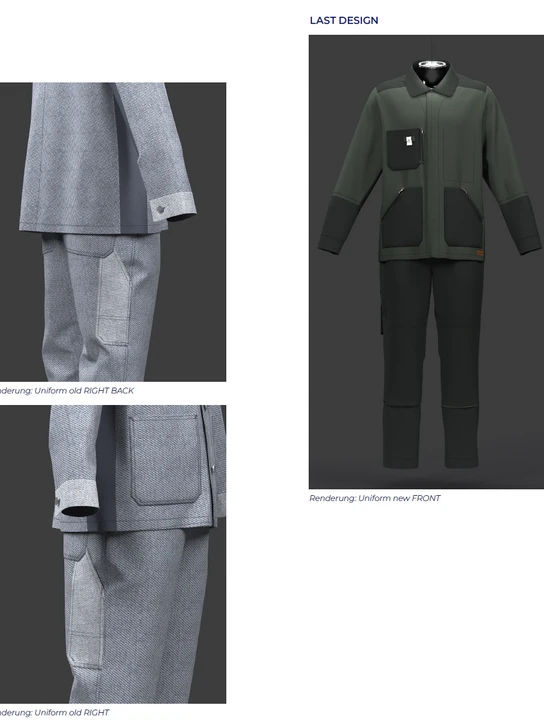

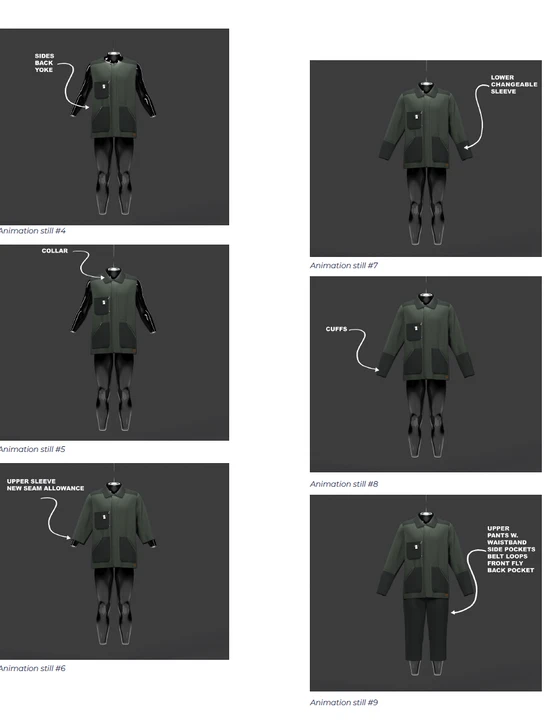

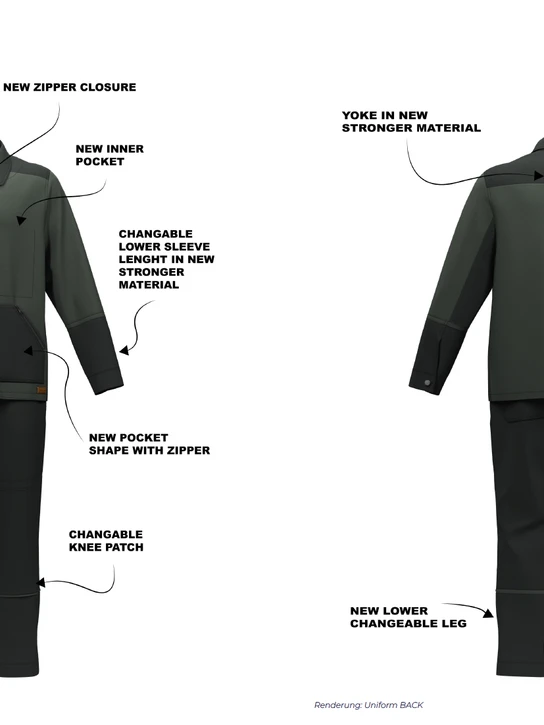

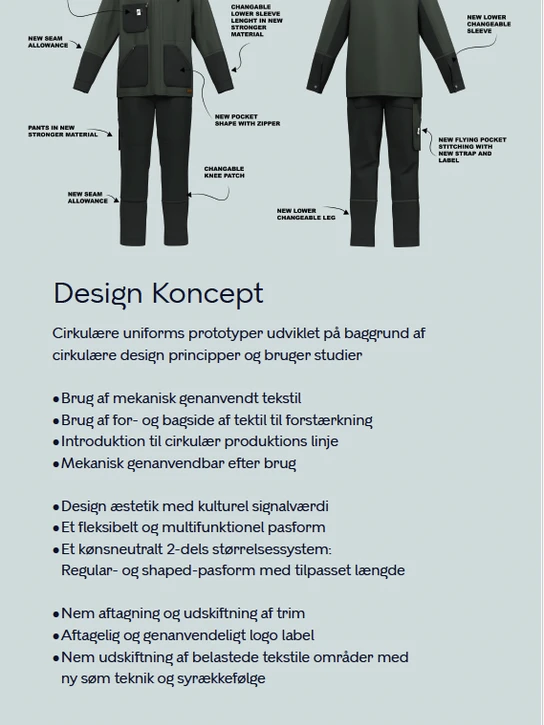

Over the past two years, the Uniforms Project has examined how design, materials, and collaborations can help reduce resource consumption and create more sustainable workwear. The findings reveal that circularity in uniforms is not just an ambition - it is a necessity for a greener future.

The project is now completed, but the work continues, building on the insights gained:

- To make workwear circular, the entire value chain must be rethought. First and foremost, we must strengthen sustainable textile strategies in public procurement. This means that public tenders must prioritize durability and recyclability. Next, we need to develop new circular design strategies for workwear. This includes focusing on replaceable wear parts, modular systems, and repair-friendly design, which can set new standards for functionality and durability. There is also great potential in material recycling, but improvements in fiber quality and production methods are necessary to meet workwear requirements. At the same time, users play a crucial role in extending the lifespan of garments, and strong partnerships across sectors are essential to creating lasting solutions, says Mette Julie Bundgaard-Nielsen, Assistant Professor at Kolding School of Design and project lead.

The project was carried out in collaboration with Kolding School of Design, Copenhagen Municipality, Wolkat, Revaluate, Fristads AB, Coor, Bacher Work Wear A/S, VIA University College, and KEA. It was funded by the Danish Agency for Higher Education and Science.